Self-made Spindle

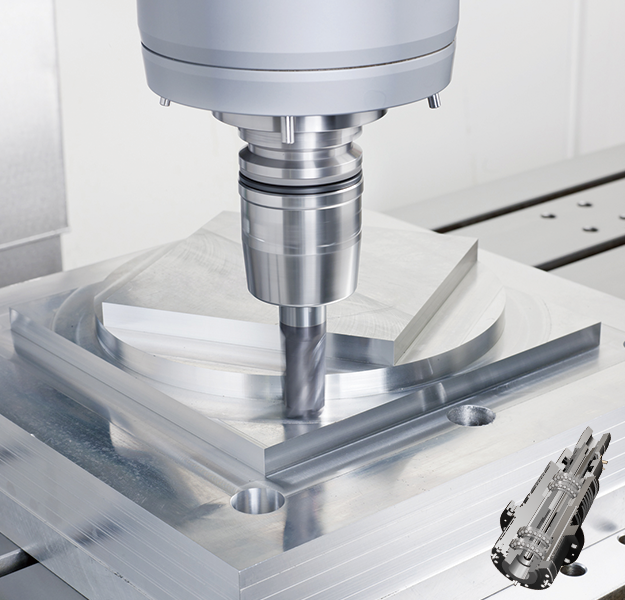

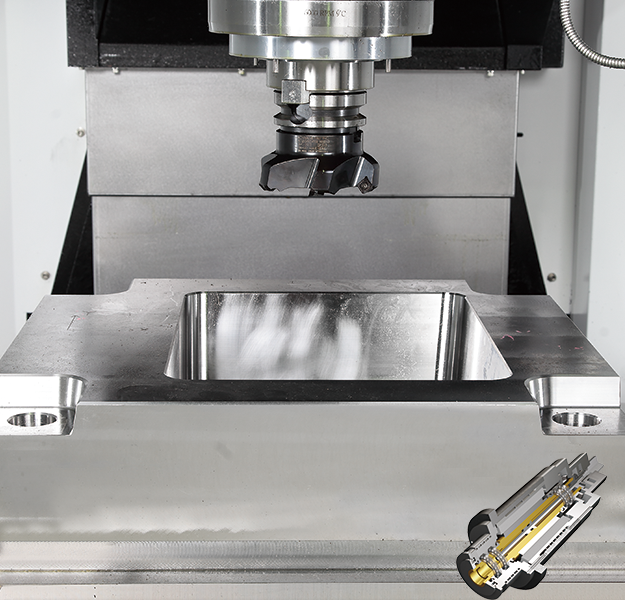

High-accuracy machining involves stability, accuracy and rigidity, provding maximum accuracy and cutting performance in effort to raise productivity and efficiency onsite.

Logout?

Log Out

Are you sure to log out ?

High-accuracy machining involves stability, accuracy and rigidity, provding maximum accuracy and cutting performance in effort to raise productivity and efficiency onsite.

Self-made spindle implements high milling, high drilling and tapping performance to meet high-quality performance.

Maximum bearing pre-load rigidity

Spindle Run Out Test: 0.002 / 300 mm 。

Temperature evaluated can be controlled in 15 ℃ under 20K high-speed machining

3D die and mold maching result can be reached up to 6000 mm / min (Model MVP-10)

Features:

High-speed Direct Drive Motor Driven

Cooling Circulation

Concentricity Calibration

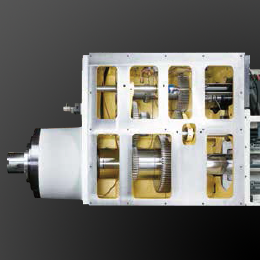

Maximum speed 8,000 rpm of Gear Type Spindle going along with DMC/Bridge Mill Modles,

providng high cutting efficiency and productivity.

Features:

1. Gear Box is placed moving up to prevent machining interference

2. Gear design is based on Japanese technique and manufacturing.

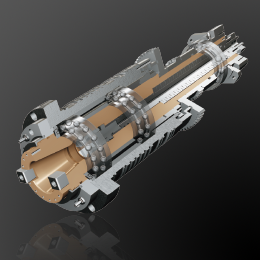

Hybrid Type Spindle featuring spindle colling design and detached spindle and built-in motoes, enabling reducing thermo displacement. Hybrid Type Spindle can go along with 5-sided DMC/Bridge Mill models and automatic angular heads.

Features:

Spindle features G-SENSOR Protection, prevening collision issue, and ensuring high accruacy and high efficiency performance.

Oil-Air Spindle Lubrication remains providing lubrication upon ball bearings of spindle, ensuring unlimited operation hours, and spindle temperature is effectively reduced in effort to improve cutting accuracy.